NEWS

A More Bio-Friendly Drifter

Drifters from the NOAA Global Drifter Array (implemented through the Global Drifter Program) provide a tremendous public service. Not only do they support scientific research on the global surface currents and sea surface temperature patterns, they contribute data to weather forecasting, marine studies, and operational programs such as hurricane forecasting. In some cases, they are also used to help track and identify the conglomerations of plastic pollution in the ocean. When drifters stop transmitting useful data, it is because they have run out of power, been washed ashore, taken from the sea by passing ships and boats, or have sunk beneath the surface, possibly to the bottom. When they are not removed from the ocean or shoreline, the drifter’s components can contribute to the marine debris problem.

To address this problem, and to lower the carbon footprint of this research, the Lagrangian Drifter Laboratory (LDL) Team transitioned their drifter production to use recycled plastic components and alkaline batteries together with low-power electronics. The team has gone a step further to start production of the SVP and wave drifters with bioplastics.

The workhorse of the Global Drifter Program is the Surface Velocity Program (SVP) drifter. The SVP drifter’s primary plastic component is the hull, which has a diameter of 35 cm and is made of acrylonitrile butadiene styrene (ABS). In 2018, the LDL moved to post-consumer recycled ABS to reduce their carbon footprint. The drogue is a cylindrical tube of rip-stop nylon fabric connected to the surface buoy with an impregnated steel wire-rope tether. A thermistor potted with thermally conductive resin encapsulated into a stainless-steel enclosure is mounted in the bottom part of the surface buoy, 18 cm below the still-water flotation line. The base of the thermistor enclosure that communicates with the inside of the drifter is thermally insulated from the inside of the buoy to prevent biased sea surface temperature readings that may occur when the drifter’s hull overheats under the sun, especially at low latitudes.

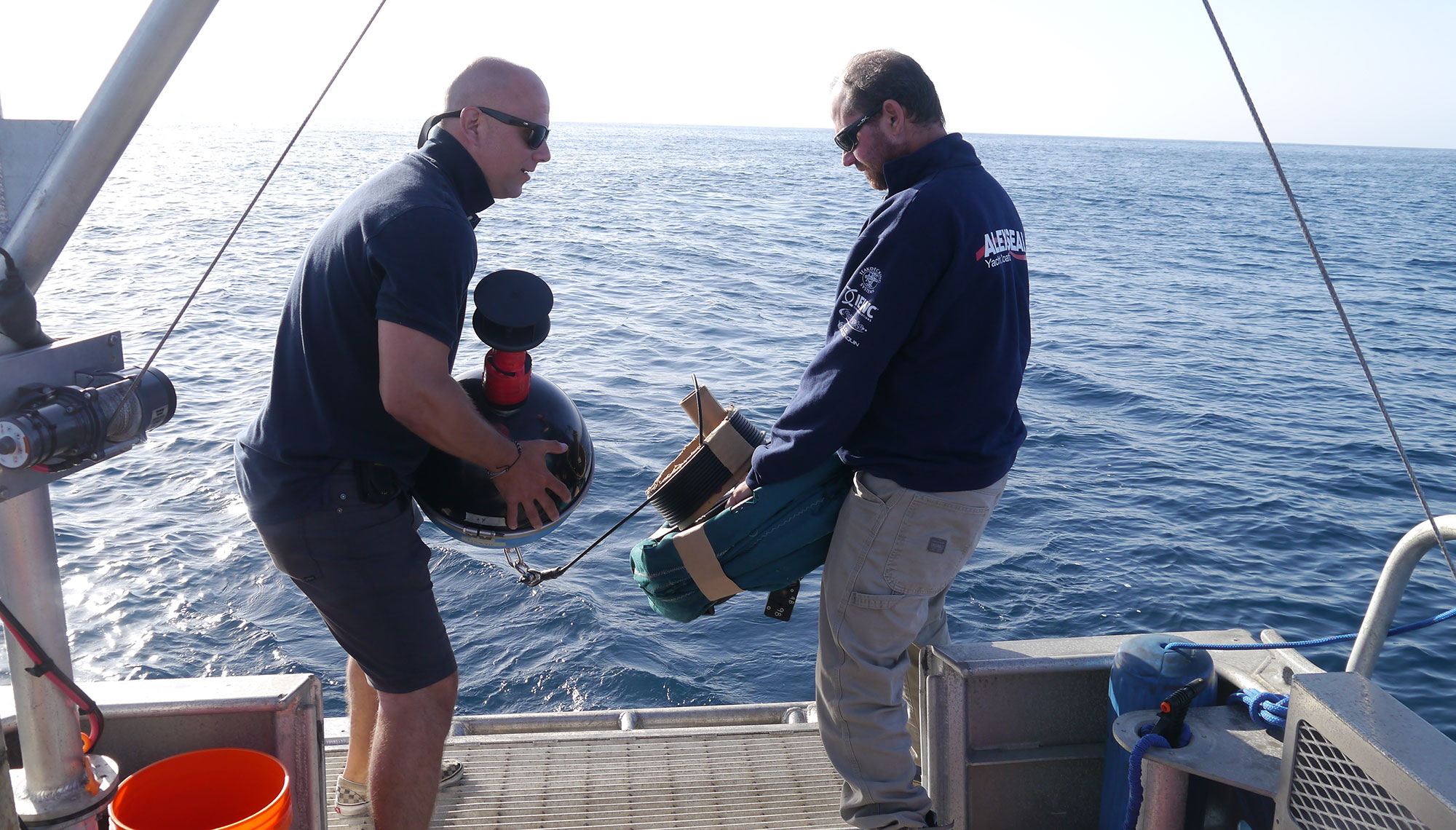

Figure 1. LDL drifter ready for deployment.

Vulcanized rubber is used for the tether’s strain relief, also known as “carrots.” The internal electronics include the Iridium modem, data controller cards, and batteries and are RoHS and CE certified. The GDP drifters are fitted with alkaline battery packs. Although alkaline cells are not designed to withstand shocks and vibrations, they are preferred because they are less hazardous than primary lithium batteries. Because the target lifetime of the drifter is in excess of 400 days, it means that through its life the surface buoy undergoes several million impacts resulting from surface waves with mean periods ranging from approximately 3 s for wind waves to about 20 s for swell (Kinsman, 1984). Alkaline batteries have a less energetic reaction with salt water than lithium batteries if the hull floods. Modern-day alkaline batteries no longer contain mercury and are classified as non-toxic or non-hazardous by the EPA. The drifter components are produced using injection molded resin using either virgin ABS or recycled ABS. The injection molding of the LDL drifters is done at a commercial facility that meets the ISO9000 and California State requirements for clean manufacturing.

The GDP drifters are primarily deployed by volunteer vessels of opportunity, including commercial ships, research vessels (doing experiments that include drifters or other work), partnerships with the US Navy and US Coast Guard, and international partnerships with research institutions, Navies, and not-for-profit organizations (most using sailing boats). The GDP does not use dedicated deployment cruises and therefore does not significantly increase the carbon-use impact of an ocean-going vessel expeditions. The deployment procedure requires the tossing over or lowering while underway of the drifter unit or packaged device. The drifter unit (unpackaged) uses only biodegradable paper tape to keep the drogue organized or when packaged it uses biodegradable cardboard or cornstarch boxes held together with dissolving biodegradable paper tape and salt blocks (Figures 1–3).

Figure 2. Drifter right after deployment.

Development of a Biodegradable GDP Drifter

The components of the GDP drifters that currently present an environmental footprint are ABS plastic, recycled ABS plastic, rip-stop nylon fabric, stainless steel fittings, wire rope, vulcanized rubber, assorted silicon chips, internal fittings, epoxydic resin, and alkaline batteries. The LDL drifter controllers are RoHS compliant as well as with California-specific regulations; the exterior protective paint is compliant with California State coastal zone regulations. After they the robust components of the drifters (including the ABS hull, wire rope, stainless-steel fittings, and nylon drogue) are no longer functional, they contribute to anthropogenic debris that follows the surface circulation of the ocean, ends up on the bottom, or strands on the shoreline.

Plastics and other artificial materials that do not readily degrade contribute to the large volume of marine debris (or marine litter) and potentially pose risks to the health of the ocean (Carpenter and Smith, 1972; Cozar, et al., 2014). The GDP is committed to goals set during the United Nations Decade of Ocean Science for Sustainable Development (2021–2030). In particular, Sustainable Development Goal (SDG) Target 14.1 aims to prevent and significantly reduce marine pollution of all kinds by 2025, including marine debris. In keeping with this goal and commitment, the GDP has been working on the next generation biodegradable GDP drifter.

The GDP is examining these long-lasting components for replacement with biodegradable components that have minimal harmful degradation residue and byproducts. Bioplastics are made from organic materials such as cornstarch and other nontoxic compounds; they can be made rigid and robust with key additives. Some biodegradable plastics are still petroleum-based plastics that are combined with an additive that makes them break down quickly. The replacement and choice of bioplastics required careful consideration and testing. Consultation with chemists indicate that a skillful choice must be made so that the bioplastics and biodegradable plastics are not quickly reduced to microplastics, creating a different pollution problem. The LDL judiciously chose a bioplastic that does not have petroleum byproducts and does not contain bisphenol A (BPA), a hormone disrupter that is often found in traditional plastics (Lithner, et.al., 2011).

This evolution of the GDP must proceed carefully in order to maintain the performance of the instruments and hence the structure and cost-effectiveness of the array. Replacement components must be chosen carefully so that the degradation processes do not contribute alternative harmful components. The concern with the existing materials is the volume of the non-degraded materials on the surface (debris contribution) and the leachates and corrosion products from the materials that become bottom or shore debris.

Figure 3. Bio drifter at work after packaging material have been shed.

References

Carpenter, E.J., and K.L. Smith Jr. 1972. Plastics on the Sargasso Sea surface. Science 175:1,240–1,241, https://doi.org/10.1126/science.175.4027.1240.

Cózar, A., F. Echevarría, J.I. González-Gordillo, X. Irigoien, B. Úbeda, S. Hernández-León, A.T. Palma, S. Navarro, J. Garcia-de-Lomas, A. Ruiz, M.L. Fernández-de-Puelles, and C.M. Duarate. 2014. Plastic debris in the open ocean. Proceedings of the National Academy of Sciences of the United States of America 111:10,238–10,244, https://doi.org/10.1073/pnas.1314705111.

Kinsman, B. 1984. Wind Waves: Their Generation and Propagation on the Ocean Surface. Dover Publications, 704 pp.

Lithner, D., I. Nordensvan, and G. Dave. 2011. Comparative acute toxicity of leachates from plastic products made of polypropylene, polyethylene, PVC, acrylonitrile–butadiene–styrene, and epoxy to Daphnia magna. Environmental Science and Pollution Research 19(5):1,763–1.772, https://doi.org/10.1007/s11356-011-0663-5.